Applications

Polyphen® can be used as part of a panel system to provide fire ratings.

Brewing companies have used the technology as fire protection in their wine tank storage farms whilst major engineering and manufacturing companies have used Polyphen® to protect their manufacturing facilities. From an architectural perspective fire rated design now doesn’t need to be compromised because of fire rating regulations. Polyphen® can be installed in sheet or laminated form and can be profile cut to +/- 0.5mm. This opens up design opportunities that have been denied in the past.

How it works

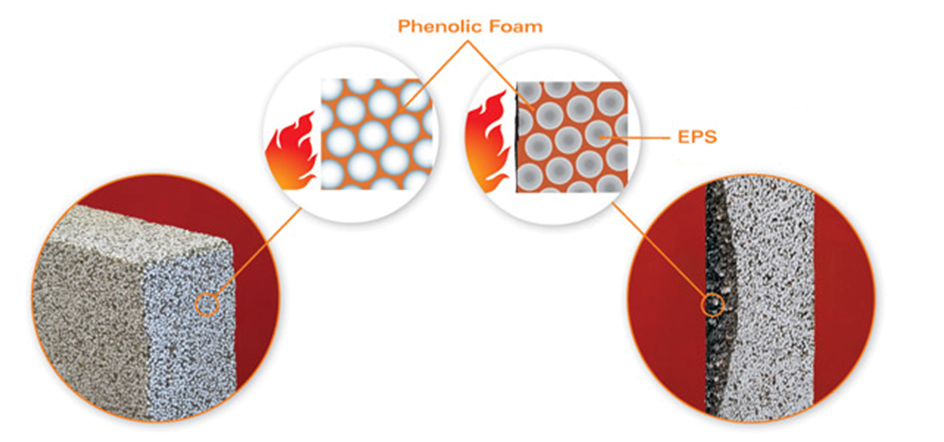

In a non-fire situation, the Expanded Polystyrene (EPS) and Phenolic matrix provides strength and insulation and when rendered makes it suitable for the external cladding of domestic and commercial buildings.

In a scenario where a fire is in close proximity to the Polyphen® foam the Phenolic part of the matrix does not burn and maintains its shape and structure.

The Polyphen® foam remains in a honeycomb shape and it is this, which acts as a fire buffer.

In addition to having good fire resistance, Polyphen® panels have been found to have low smoke generation, passing tests to meet FM Standard 4882 for Smoke Sensitive Occupancies.

Innovation

Polyphen® is a company driven by innovation. We have pioneered Fire-resistant product technologies, leading the development of innovative product solutions for our customers through local and international resources.

We are committed to working with our customers to deliver high quality creative solutions to construction problems. Contact us and see how the innovative approach using Polyphen® in building construction can help you.

Environmentally Sound

The energy saved over a lifetime of an insulation panel in reduced heating, more than compensates for the raw material used in its’ construction.

No ozone depleting blowing agent is used in the foaming process. Polyphen® can be recycled at the end of its’ use. The production process is highly energy efficient as the chemical reaction creates sufficient heat to drive the foaming process without external heat impact.